Examine This Report on Premier Aluminum Llc

Table of ContentsSome Of Premier Aluminum LlcSome Known Incorrect Statements About Premier Aluminum Llc The Definitive Guide to Premier Aluminum LlcMore About Premier Aluminum Llc

(https://www.video-bookmark.com/bookmark/6655034/premier-aluminum-llc/)Using low expense and unqualified distributors can cause high quality problems, and lost time and cash in the long run. To aid you via the procedure, right here are some things to take into consideration when picking the ideal steel spreading vendor.

As an example, a business that just utilizes the investment casting procedure will try to market you on why that process is best for your application. But what if using the sand casting procedure is best for you and your needs? Instead, try to find a vendor that offers a series of casting procedures so the finest alternative for YOU is selected

If collaborating with a solitary source for every one of your spreading needs is vital to you, the provider requires to be varied in its abilities. When integrated with various other incorporated capacities, this can aid simplify and press the supply base. When selecting the best spreading supplier, careful consideration must be offered to high quality, service, and cost.

Premier Aluminum Llc Can Be Fun For Anyone

Customers increasingly choose casting distributors who have machining abilities. If the spreading distributor uncovers an issue during machining, the trouble is dealt with much faster with no disagreement over whose fault it is.

What do you need from your casting vendor? Are you looking for a person to simply supply a metal element to your front door or do check these guys out you need extra?

Others will certainly exceed the letter of the PO to aid you save money and time. Do you have requirements for both ferrous and non-ferrous alloys? Some factories are limited or specialized. Ensure the supplier can satisfy all your product or alloy demands to remove the need for numerous providers.

Premier Aluminum Llc Things To Know Before You Buy

Study the vendor's website. Talk to a sales representative or business partner.

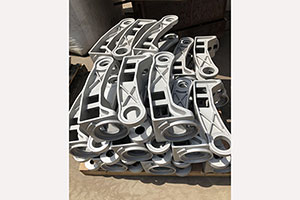

Light weight aluminum is also light-weight and has excellent rust resistance, making it excellent for applications where weight and durability are necessary variables. Furthermore, aluminum spreading is an affordable method of production, as it needs less energy and resources than various other methods. Iron spreading, on the other hand, entails pouring liquified iron into a mold and mildew to produce a desired shape.

Get This Report about Premier Aluminum Llc

Iron casting is likewise able to stand up to high temperatures, making it appropriate for usage in applications such as engine components and industrial equipment. Nonetheless, iron casting can be much more pricey than aluminum casting because of the greater price of raw materials and the energy called for to melt the iron. When determining between aluminum casting and iron casting, it is necessary to consider the particular requirements of the application.

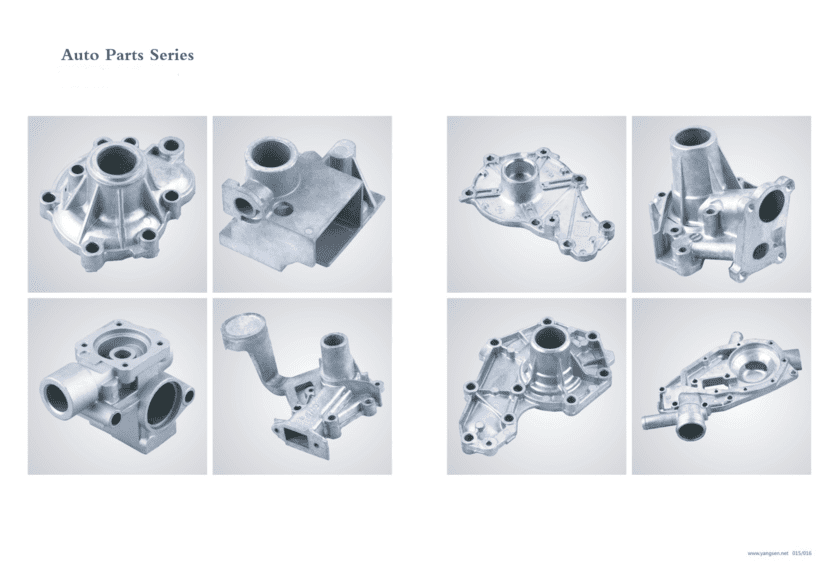

In verdict, both aluminum spreading and iron spreading have their own one-of-a-kind benefits and disadvantages. There are three sub-processes that drop under the category of die casting: gravity pass away casting (or permanent mold and mildew spreading), low-pressure die spreading and high-pressure die spreading. To obtain to the finished item, there are 3 key alloys used as die casting product to choose from: zinc, aluminum and magnesium.